Workshop

Electronic Repairs

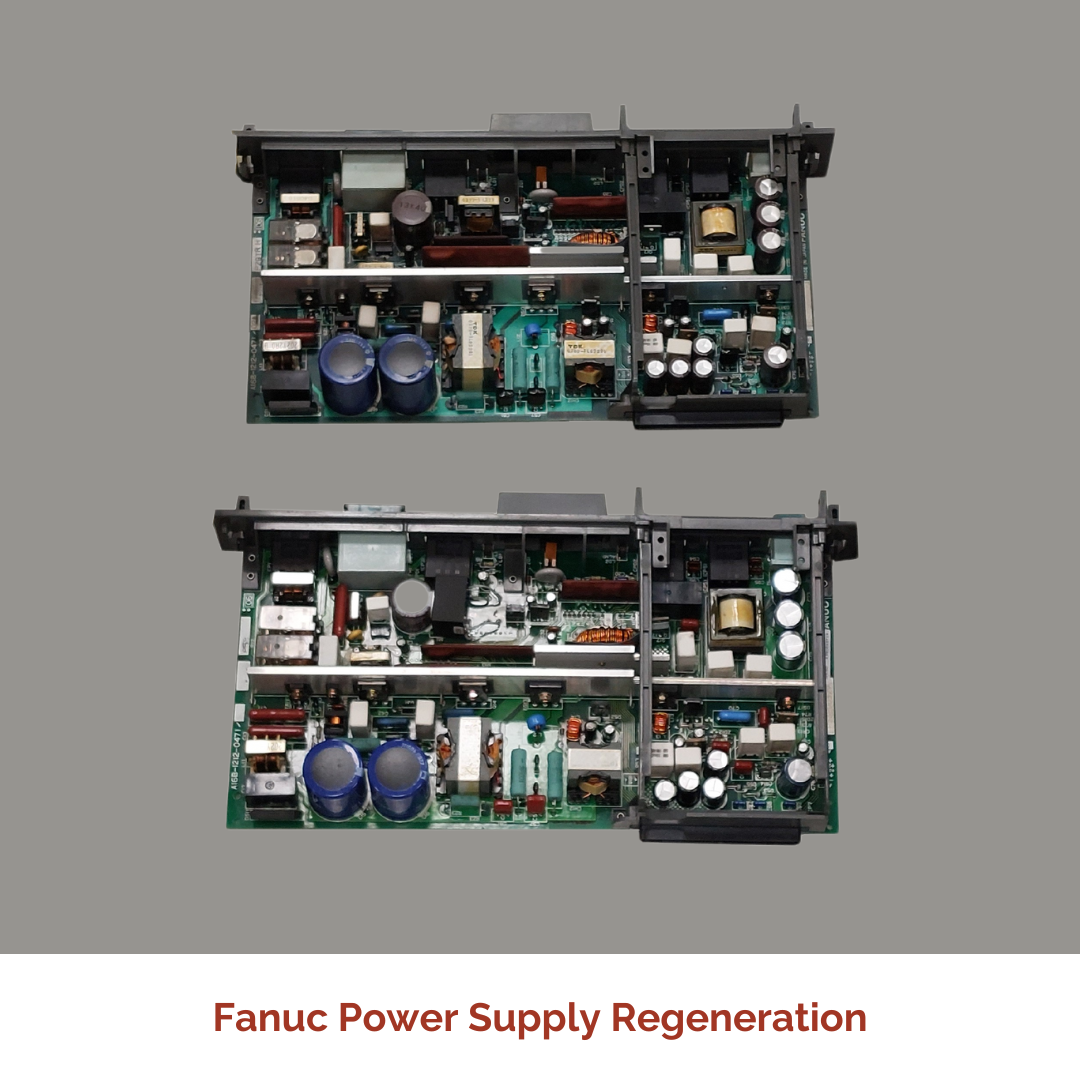

Electronic repairs for CNC machines

The Assistec in-house repair laboratory was created to meet the needs of an ever-increasing number of client companies that required electronic spare parts for CNC machine tools available quickly and at competitive prices.

Over time, the repair workshop has become the company's state-of-the-art centre; it houses a staff of highly specialised electronic engineers and technicians with decades of experience, at the service of the customer.

Using the latest technology, the staff of electronic engineers and highly specialised technicians are able to repair all Fanuc, Mitsubishi and major machine tool manufacturers' equipment:

- Axis Drives

- Power Supplies

- I/O Boards

- GOP Mori Seiki

- Spindle Drives

- Mori Seiki Mapps

- Operator Panels

- Industrial PCs

- CNC

- Chiller Units

- LCD Units

- Safety Control Units

- Spindle Motors

- Axis Motors

- MDI Units

Fast and guaranteed

All equipment is repaired, overhauled, washed and tested under load.

In addition to replacing the components causing the failure, all parts that are subject to deterioration are always replaced as a preventive measure.

The washing of electronic and aesthetic components is very important, as the presence of oil residues, dust, dirt and oxidation on the boards would impair their reliability.

Thanks to these processes and the intensive load testing to which we subject all repaired equipment, we can offer our customers up to 24 months warranty and even a lifetime warranty on some maintenance contracts.

In fact, thanks also to our large stock of spare parts, we can restore and return repaired equipment to the customer in just 2-3 working days.

Hydraulic power unit overhaul and repair

We performed a complete overhaul on a DAIKIN hydraulic power unit, which also included repairing the inverter section. Our technicians replaced the fan, cleaned and flushed the radiator, installed new vibration dampers, and replaced worn pipes and the pump unit. The process ended with a load test in our workshop, ensuring that optimum performance was restored.

Mori Seiki Mapps Repair: Our Lab's Unique Service

Our workshop offers a repair service for Mapps Mori Seiki systems. The process begins with an accurate diagnosis of the fault, followed by disassembly and repair of the faulty component.

We use state-of-the-art diagnostic tools to ensure that we correctly identify each problem, thus guaranteeing a precise and effective intervention. Once the fault has been identified, we proceed with the disassembly of the faulty component. Each step in the process is carried out with the utmost attention to detail to avoid further damage and preserve the integrity of the system. Next, we intervene directly on the fault, using our advanced repair techniques.

After meticulous cleaning of all components and reassembly of these together with the repaired component, the Mapps is ready for the final stage.

We perform a final test on the entire system, simulating real operating conditions to verify that everything works perfectly. This allows us to ensure that the machine is operating at peak efficiency again.

The most common problems we solve are display difficulties, backlighting, system lock-ups, communication problems with the numerical control, and start-up difficulties.

Our expertise in Mori Seiki Mapps systems allows us to provide solutions that not only solve problems, but improve the reliability and performance of your machine tools.

Would you like to know in detail the services our Electronic Repair Workshop can offer? Fill in the form below!

_240522112755.jpg)

_240522112755.jpg)

_240522112755.jpg)