Tool Monitoring and Anti-Collision Systems

SBR - TOOL AND PROCESS MONITORINGWith the installation of intelligent sensors on the machine and a software, Assistec monitors the state of tool wear and the production process Advantages |

|

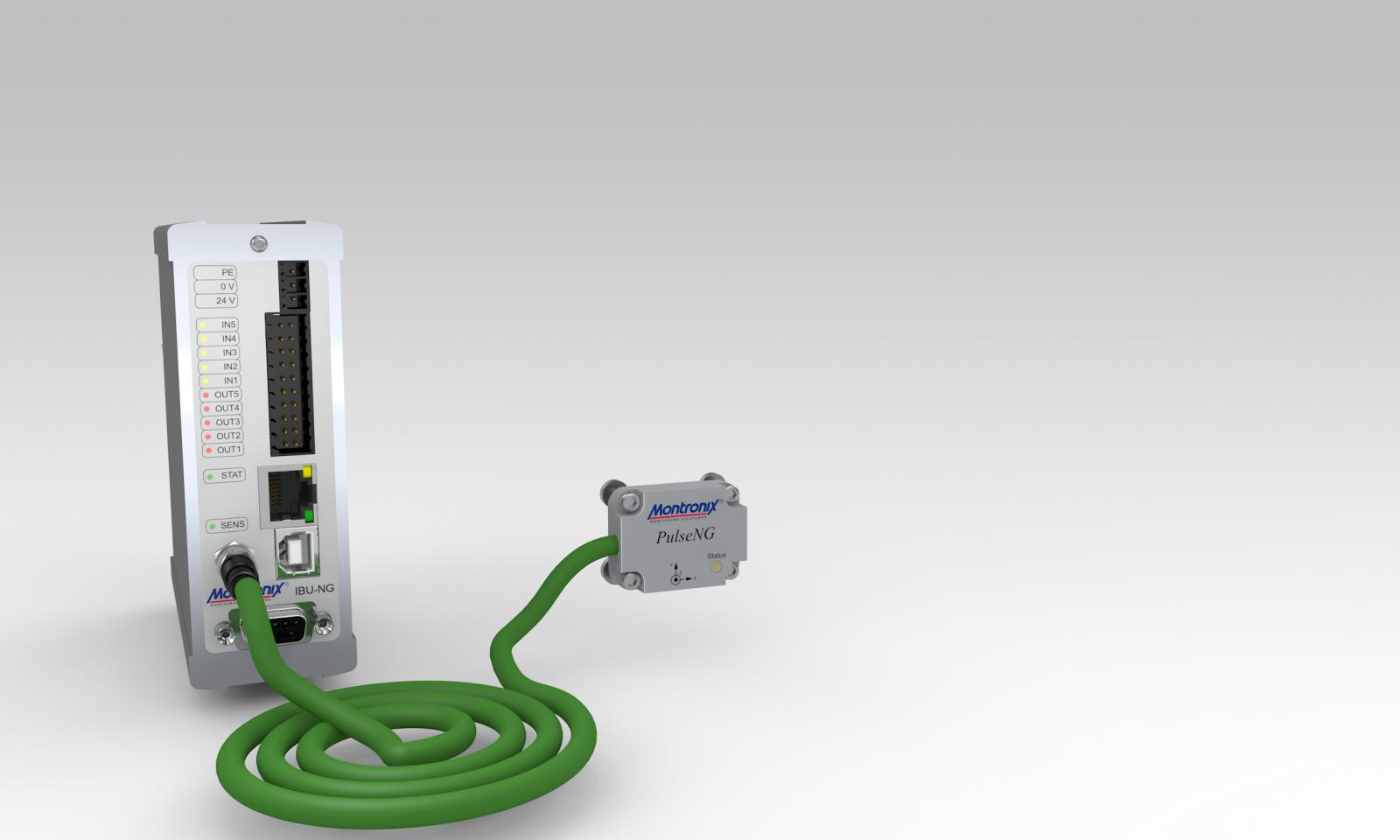

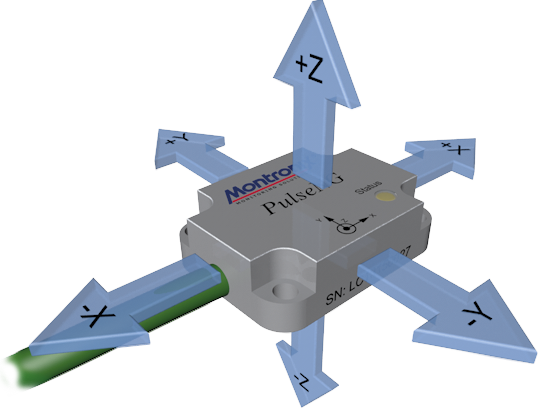

PULSE NG - COLLISION DETECTION AND MONITORINGThe 4.0 Ready PULSE NG system is the ideal solution to protect the CNC machine. 1. Protection of the machine in the event of collisions |

|

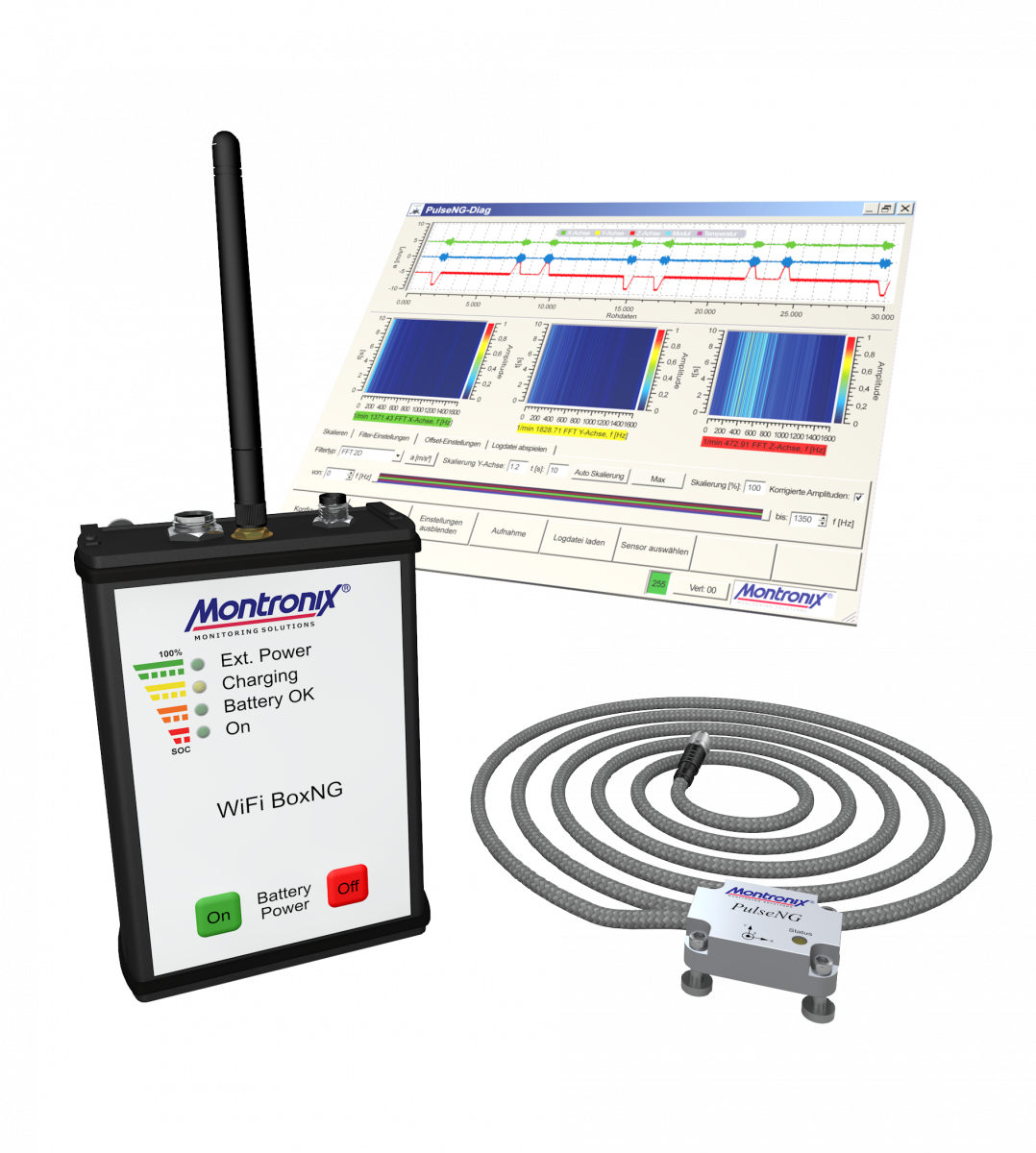

WIFI BOX NG - MACHINE STATUS MONITORINGPortable Wi-Fi diagnostic system that detects problems on machine parts |

|