News and Press

The differences between traditional machine tools and CNC machines

Conventional machine tools and computer numerical control (CNC) machines are both used for machining, but have significant differences in several key practical aspects.

So, if you are wondering whether CNC machines are better than traditional ones or whether it is time to replace your machines with automated solutions, below you will find all the elements you need for an in-depth evaluation of the question.

We have examined 7 evaluation criteria, making an objective judgement for each of them based on the practical applications of the machine type.

Read more

What is a CNC lathe and how does it work?

What is the CNC lathe and how does it work?

The computer numerical control (CNC) lathe is one of the most advanced and precise tools in the field of machining. Its ability to perform complex machining operations with high precision and repeatability has, after all, revolutionised the manufacturing industry, significantly optimising production processes in many sectors. In the following lines, we will explore in detail how the CNC lathe works, analysing its main components, the programming process and practical applications.

We will also look at the interactions between hardware and software, the types of tools used and how machining parameters are controlled, to summarise the potential of a technology that has become strategically relevant today.

Read more

Team Building Assistec!

An Evening of Cohesion and Fun for Our Team!

On Friday 31 May, we spent the late afternoon and evening in cohesion and fun with activities that strengthened the bonds between us.

Activities held:

- An exciting quiz on our company, where we tested our knowledge and shared laughs.

-A table-football tournament where great talent and team spirit emerged, also showing the competitive side!

To end on a high note, we had a company barbecue in collaboration with Grill Street BBQ, a perfect opportunity to relax after the different matches!

P.S.: The photos are not great, but it's a sign that the afternoon was fun!

Read more

Assistec sponsor for NATIONAL BBQ CHAMPIONSHIP

This past weekend, our company had the honour of being a sponsor of the NATIONAL BBQ CHAMPIONSHIP, an event officially sanctioned by the World BBQ Association WBQA, which was held in Campagnola Emilia, in the province of Reggio Emilia!

It was an extraordinary experience, full of flavours, exciting competitions and unforgettable moments. We had the opportunity to meet BBQ enthusiasts from all over Italy, supporting the best grill masters in the country.

We are happy to have been part of this adventure!

Read more

CNC metal and plastic machining: how does it work?

CNC machining of metals and plastics has a number of applications in contemporary industry and makes it possible to obtain extremely precisely designed components, whatever their size.

In fact, CNC (Computer Numerical Control) machining has revolutionized the manufacturing sector because it has offered companies the ability to shape metals and plastics with unparalleled flexibility.

This is why we want to go into more detail about CNC machining of metals and plastics, delving into the features, advantages and applications of this innovative process.

Read more

CNC programming: from the basics to advanced strategies

CNC programming: a complete guide

Programming a computer numerical control machine, also known as a CNC machine, is not a simple operation, and requires a certain amount of experience in the field. When we talk about CNC programming, we’re referring to the process of creating computer commands, generally G-codes, used to control these automated production tools, able to carry out precise and complex operations, often for the metalworking sector, such as cutting, milling and drilling on a variety of materials. These instructions include: information on the movements of the tool, the speed of the spindle, feed rates, tool changes and other parameters necessary to carry out a particular process. Each process in the programming of the CNC machine tool is carried out using an integrated electronic device, usually an on-board computer.

Read more

We are in the new issue of TECNÈ, which has dedicated its cover story to us!

A single, evolved partner

Since it was founded 25 years ago, Assistec has developed its service offering with increasingly innovative proposals. Today, the company also stands out by offering modular robot cells and an advanced service concept

by Andrea Pagani

Evolution is the basis of adaptation and survival of species. It applies in biology as well as in economic and industrial dynamics: markets change, technologies update, companies evolve.

Antonio La Placa's story is a striking example of this evolutionary capacity: after gaining extensive experience in Germany as a FANUC technician, in 1998 he returned to Italy where he founded Assistec. Initially focused on the electronic technical support of CNC machine tools for chip removal equipped with FANUC components (numerical controls, motors, drives, power supplies, electronic boards), he soon expanded his offer with additional, increasingly advanced services.

Read more

Assistec returns to Mecspe 2024

From 06 to 08 March at Bolognafiere, MECSPE 2024, the largest event dedicated to innovations for the manufacturing industry, returns.

Assistec will be present at the exhibition with a stand in Hall 30, Stand A54.

At the Assistec stand you will be able to discover the latest in automation and control systems for the manufacturing industry.

Visit our stand to find out more!

Read more

Types of CNC machines: applications and differences

Exploring the different types of CNC machines

It's clear that the market for CNC machine tools is just as varied as the tasks these machines have to perform. This is because, with the advent of Industry 4.0 and modern smart factories, these machines have gradually taken on a more predominant role within industries, particularly manufacturing. CNC technology offers efficiency, precision and consistency, which are difficult to achieve with manual machining processes. There are various methods for classifying CNC machines, most of which are based on their design and intended tasks. Among the various types of CNC machines are milling machines, lathes, laser or plasma cutting machines, drilling machines, and grinding machines. They each have their own unique features and functionalities that can be customised using computer-aided design (CAD) and computer-aided manufacturing (CAM) programs, enabling precise control over the movements of cutting tools and workpieces.

Read more

The importance of CNC machine tool overhaul

CNC machine tool maintenance: a guarantee of optimal performance

The maintenance and overhaul of CNC machine tools should not be confused with their repair. While repair is requested by the customer when a machine malfunctions, causing an emergency that could also lead to a halt in production, an overhaul is a scheduled or planned intervention conducted in agreement with a technological partner. During an overhaul, the machine is completely disassembled, and each individual component is carefully analysed and, if necessary, replaced or repaired. Regular overhauls are essential to ensure efficiency, precision and longevity of CNC machines. This preventive and proactive approach enables the resolution of minor issues before they cause serious damage.

Read more

The future of CNC machine tools: Artificial Intelligence

AI at the service of machine tools

Artificial Intelligence is now among us. Just as electricity did a hundred years ago, AI today promises to change the world. No industrial sector is exempt from this epoch-making change, from the food industry to manufacturing, to mechanical engineering and many others. In addition to being on everyone's lips, the advent of Artificial Intelligence is increasingly imposing itself in the world of work, marking a new step forward for Industry 5.0, so much so as to raise legitimate concerns as opposed to great expectations from the point of view of technological optimisation in contemporary smart factories. In particular, with regard to integration with the CNC machine park, the coupling of automated systems such as robots and cobots, and the improvement of production flow and safety in the workplace.

Read more

Machine tool maintenance: how to extend the life of numerically controlled machines

The importance of preventive maintenance for CNC machine tools

Just like any other equipment within a company, it is crucial to check the health of machine tools. Failure to do so can result in very serious risks, including decreased productivity, machine downtime and even unexpected repair expenses. This is why, in recent years, many manufacturers have embraced a philosophy of prevention by conducting regular and rigorous checks on CNCs and replacing mechanical and electrical components subject to wear and tear. Otherwise, meeting the standards demanded of a modern smart factory operating within an Industry 4.0 supply chain would be impossible.

Read more

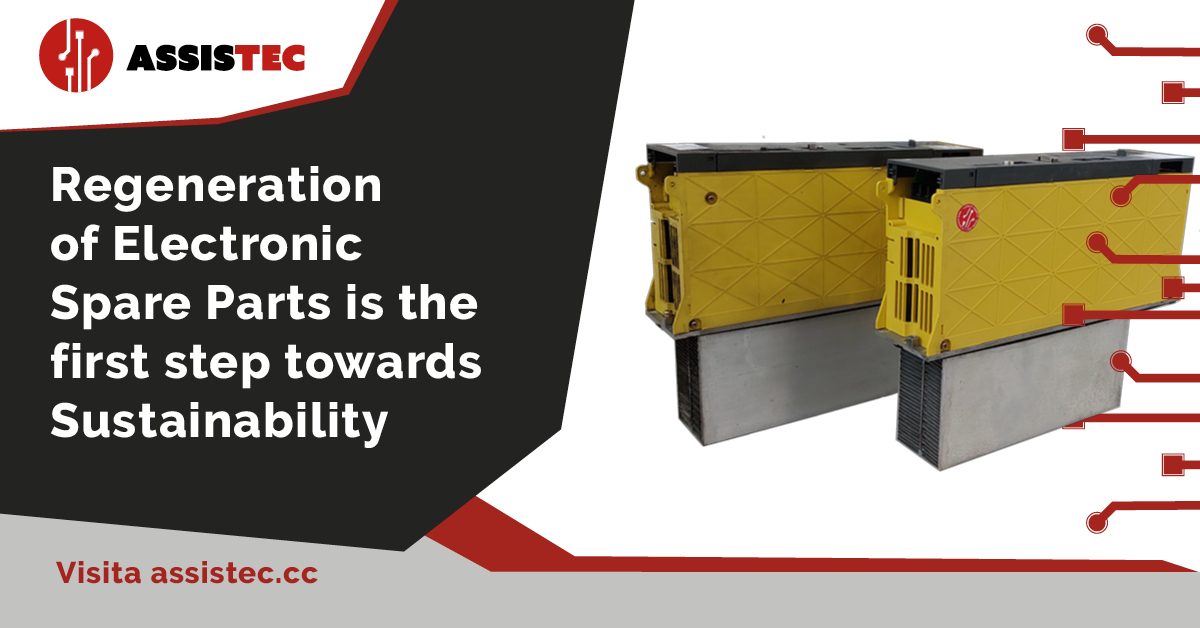

Regeneration of Electronic Spare Parts is the first step towards Sustainability

Regeneration of Electronic Spare Parts is the first step towards Sustainability

Nowadays, there is a lot of discussion about environmental and social sustainability, raising various questions about how we can achieve the goals laid out in the Agenda 2030, which was drawn up and signed by the United Nations. In a global context where it is necessary to bring about change, we at Assistec are increasingly recognising the importance of embracing an innovative mindset based on the concepts of Sustainability and Circular Economy.

Read more

Our mechanical support services for machine tools

Mechanical support on machine tools

Do you own a metalworking business? How often have malfunctions prevented your machine tool from starting or triggered emergency alarms? Every time it happens, not only is valuable time wasted, but there is also the risk of more severe consequences, such as a production halt or financial loss. Rely on Assistec for the mechanical servicing of your machine fleet, ensuring optimal functionality of your industrial equipment.

Read more

.jpg)

Why does annual scheduled maintenance pay off?

Più Increased safety for your machine tools

Numerical control machines play a central role in modern smart factories that have embraced the benefits and challenges of Industry 4.0. Affinché However, they must function optimally in order to consistently perform at their maximum capacity. Otherwise, there is a risk of unforeseen production slowdowns, machine downtime and, in some cases, even severe damages and financial losses. How can we prevent these risks? By scheduling an annual electronic and mechanical check-up. Performing scheduled preventive maintenance on your CNC machines means safeguarding the well-being of your personnel and the entire production chain.

Read more

Four tips for choosing the best service centre for your CNC machines

Maintaining your fleet of machines

If you own a mechanical workshop or smart factory operating in the agricultural machinery or packaging sector, and you work with CNC machinery, choosing the right assistance service for your machine fleet can significantly impact the quality of your work and the final product. This is why it is always a good idea to partner with an experienced provider specialising in the mechanical and electronic servicing of machine tools.

Read more

In June edition, Tecné magazine dedicates extensive space to Robofeed Flexi

The collaboration of Assistec with SCHUNK resulted in the Robofeed Flexi-RC2 line, a modular robotic island that can serve up to three machine tools.

Read more

Services and products to support machine tools

A dynamic company that offers technical, electronic and mechanical support for machine tools, as well as spare parts, repairs and robotic automation systems. Massimo Mora, Sales Manager of Assistec, tells us about it.

Read more

(1).jpg)

Prevent machine downtime with CNC maintenance

We are the ideal partner for your business, a company that has been operating for more than twenty years in Reggio Emilia, in the heart of robotics and industrial automation.

Read more

Assistec is taking part in MECSPE 2021, the reference fair for the manufacturing industry

Appointment at Bologna Fiere from 23 to 25 November Hall 30, Stand E06 to discover our Robofeed automation solutions and system integrator interventions on the CNC.

Read more